The types of cabling for PAGA systems are central to its effectiveness, ensuring that the system is robust, reliable, and capable of transmitting signals accurately in challenging environments.

In process industries where safety and effective communication are paramount PAGA systems play a crucial role. These systems are designed to broadcast important messages, announcements, and alarms throughout industrial facilities, ensuring workers remain informed and safe.

Types of Cabling

Let's explore the various types of cabling commonly employed in PAGA systems within process areas.

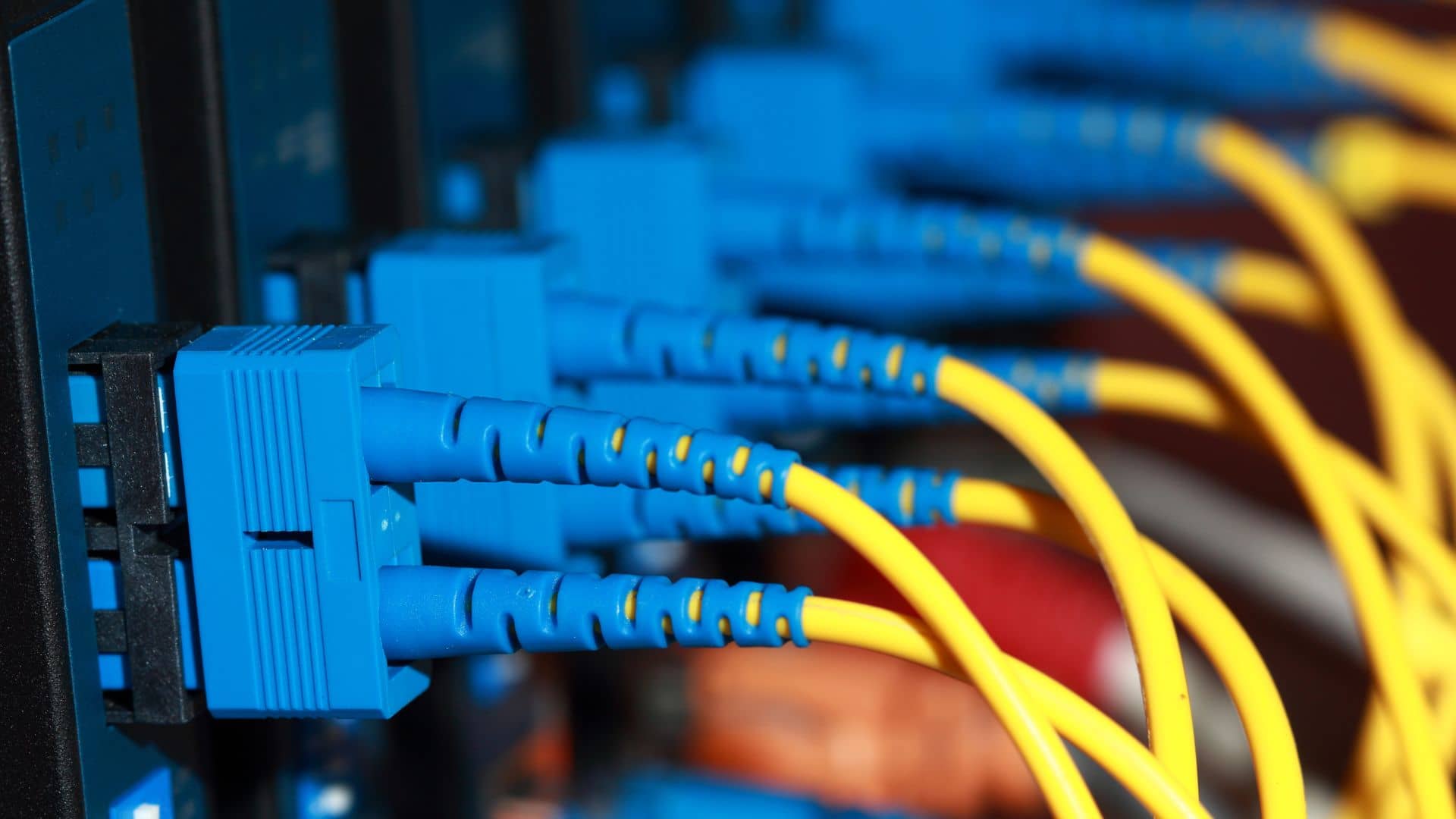

Fiber Optic Cabling

Fiber optic cabling is a preferred choice for PAGA systems in process areas due to its numerous advantages. Data is transmitted via light pulses through strands of glass fibers, offering high bandwidth, immunity to electromagnetic interference (EMI), and excellent signal integrity over long distances. In process areas where electrical noise and harsh environmental conditions are prevalent, fiber optic cabling ensures reliable communication and minimizes the risk of signal degradation or loss.

Twisted Pair Cabling

Twisted pair cabling, including shielded and unshielded twisted pair (STP and UTP), is another commonly used cabling solution for PAGA systems in process areas. These cables consist of insulated copper wires twisted together, which helps reduce electromagnetic interference and crosstalk. While not as immune to noise as fiber optics, twisted pair cabling remains a cost-effective and reliable option for short to medium-range communication within industrial environments.

Coaxial Cabling

Coaxial cables feature a central conductor surrounded by layers of insulation, shielding, and an outer conductor. This type of cabling offers excellent signal transmission characteristics and is suitable for both analog and digital PAGA systems. It provides superior shielding against EMI and is often used in environments where ruggedness and durability are required. However, coaxial cabling may be more susceptible to signal loss over long distances compared to fiber optics.

Ethernet Cabling

Ethernet cabling, particularly twisted pair cabling using the Ethernet protocol, is increasingly utilized in modern PAGA systems for data transmission and networking purposes. Some offerings include high-speed communication and are compatible with standard networking equipment, facilitating integration with other industrial automation systems. With proper shielding and installation practices, Ethernet cabling can effectively meet the communication demands of PAGA systems in process areas.

Fire Resistant Cabling

Where fire hazards are a concern, fire-resistant cabling is essential to ensure the integrity and functionality of PAGA systems during emergencies. Fire-resistant cables are designed to withstand high temperatures and maintain their structural integrity, allowing critical communication pathways to remain operational even in extreme conditions. They often feature specialized insulation and sheathing materials that prevent the spread of fire and smoke, safeguarding both personnel and assets.

Get the Right Team

By understanding the characteristics and capabilities of these cabling options, organizations can deploy robust and reliable PAGA systems that enhance safety, communication, and operational efficiency in process areas.

Team Vivo has over 10 years of experience in the commissioning and installation of Telecom, IT & ELV systems for harsh and hazardous environments. We are well-versed in industry regulations and are familiar with the different types of cables used in process areas.