Through our experience in designing, installing and supplying PAGA systems for a range of industries, we have realized that the most important aspect is to have a clear project plan, with a detailed engineering output.

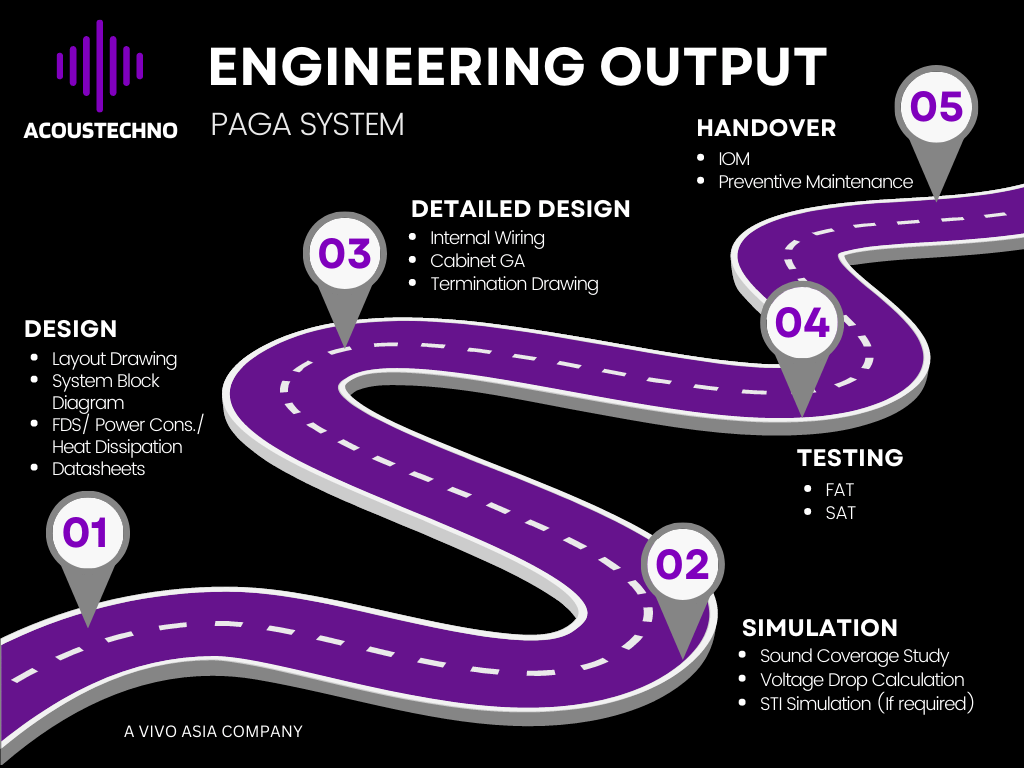

Our typical engineering roadmap for PAGA systems is as follows.

Stage 1: Design and Planning

The first stage is about Design, including layout drawings, system block diagrams, heat dissipation calculations and datasheets. During this stage the Functional Design Specification document is drawn up and client approval is received. This stage takes into consideration specifications, standards and plant layout to streamline the project planning process.

Stage 2: Simulations

The second stage is to conduct simulations such as sound coverage studies, voltage drop calculations and a STI simulation if required. Simulations play a crucial role in the engineering process of a PAGA system by aiding in design, performance evaluation, prediction, optimization, and training. They enable us to make informed decisions, ensure system compliance, and enhance the overall effectiveness and reliability of the PAGA system.

Stage 3: Detailed Drawings

In this stage, strict attention to detail is paid to complete the detailed design aspects of internal wiring, cabinet GA and termination drawings. Detailed drawings are created to specify the exact configuration, layout, and interconnections of system components, such as speakers, amplifiers, control units, and cables. The detailed drawings stage is a critical step in the PAGA system process, as it transforms the conceptual design into a precise and actionable plan. The drawings provide the necessary information for procurement, installation, and commissioning, ensuring that the PAGA system is implemented correctly, and functions as intended.

Stage 4: Testing

This includes the Factory Acceptance Test (FAT) and the Site Acceptance Test (SAT). At this stage, Component Testing, System Integration Testing, Audio Intelligibility Testing, Alarm Response Testing, Performance Validation and Documentation and Reporting are conducted.

In a FAT, a sample of speakers from each zone is tested for functionality. External system inputs are simulated, such as the fire detection system. In a SAT is where the entire system is tested thoroughly. Every speaker, every beacon light and every button on an access panel is tested. Any changes required are implemented and technical issues are resolved.

Stage 5: Handover

At the handover stage a fully functional system is commissioned, with all the operational manuals and if required, training is provided for the client. Preventative maintenance aspects that are industry specified to ensure that the system is functioning well are carried out at regular intervals of 3 to 6 months and logged carefully.

The Right Team

It is vital to get the right team on the job when installing systems such as the PAGA system for harsh and hazardous environments.

Over the past 10 years, Vivo Asia has become an expert in installing PAGA systems, with a clear plan and an efficient project delivery process by following this engineering roadmap for PAGA systems.